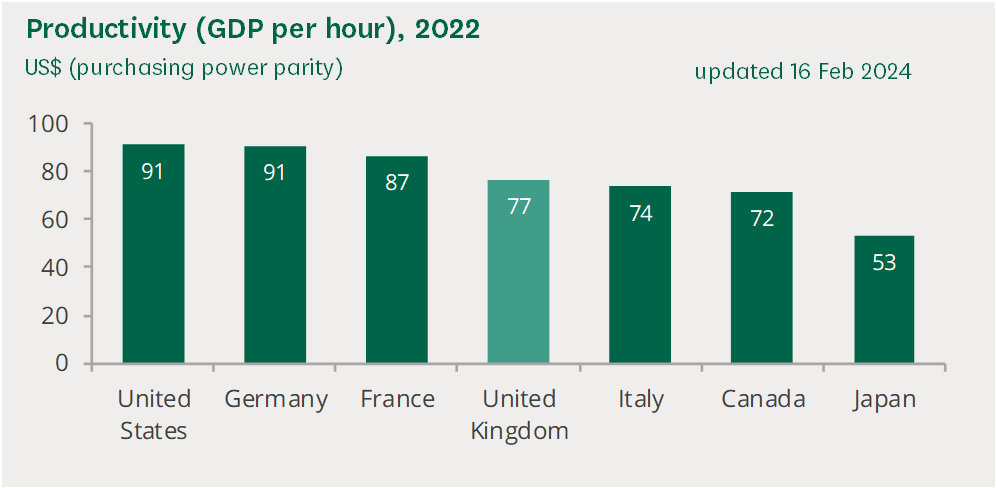

Source: House of Commons Library. Productivity: Key Economic Indicators

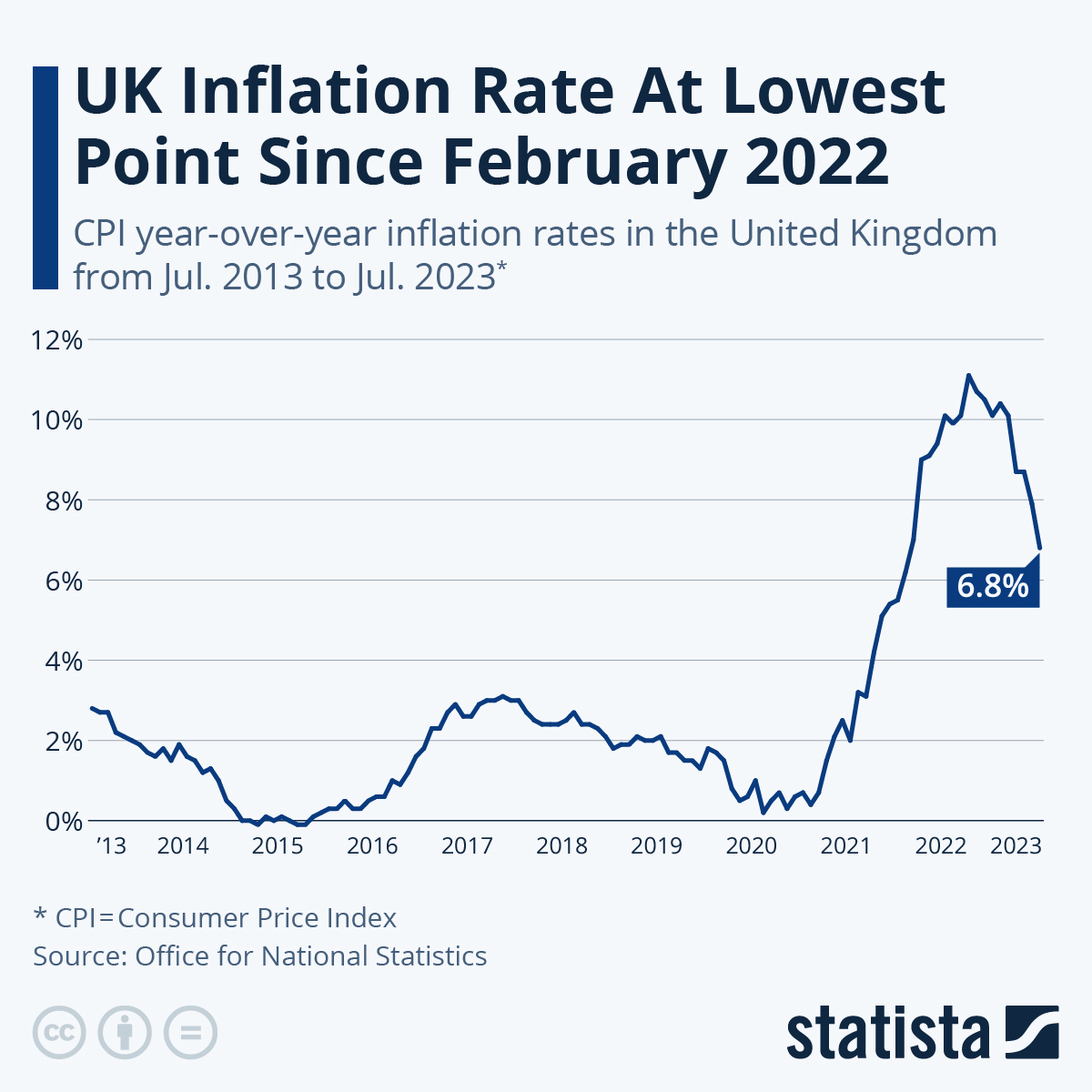

Similarly, while government policies on investment incentives or tax relief can provide temporary boosts, they often fail to address underlying systemic issues. For example, significant investment has flowed into digital infrastructure and startup ecosystems, yet productivity growth remains tepid. The reason? These investments are not always aligned with a coherent strategy that addresses the specific needs of businesses or the economy at large. The Government funded UK Productivity Commission set up by the National Institute for Economic and Social research has noted a North/South divide with London performing well but cities in the Midlands and North of England, suffering from poor communications and investment in skills. Lagging sectors include manufacturing, Finance, Insurance and Communications technology.

What else could be drivers? Ross Clark, writing in the Spectator last September had some good ideas. Did the plentiful availability of Eastern European labour replace any incentive for investment in automation? Did the Equality Act of 2010 make it harder to recruit and manage the productivity performance of the workforce? Is the post-pandemic pattern of increased working from home, focus on work-life balance and mental health awareness, also contributing to our challenges in increasing productivity?

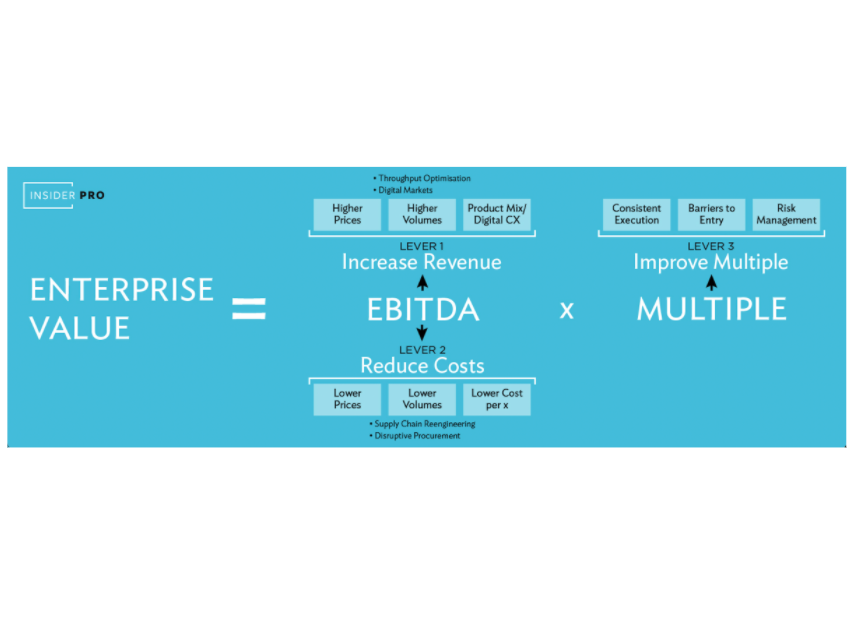

True productivity enhancement comes from within the organization. It involves rethinking how tasks are allocated, how teams are structured, and how outcomes are measured. It requires a shift from traditional hierarchies towards more agile, collaborative work environments that empower employees and foster a culture of continuous improvement.

- Reduce the number of meetings your team is involved in - evaluate the necessity of every meeting.

- Invest time in making sure everyone, at all levels, understands the 3 most important things the team will deliver, each quarter.

- Focus half a day a week on getting your team together in one room, to agree who is doing what and what they are not doing. Follow up each week to review activity.

- Use Whatsapp within small groups to communicate quickly - include urgent information, and lots of good news to help motivation and a sense of healthy competition.

- Meanwhile, encourage people to speak to each other 1-2-1, to iron out issues and clarify who is doing what.

In this era of unprecedented change, the UK has the opportunity to redefine its productivity narrative, building on its historical resilience and forward-thinking leadership. The solution lies not in the hands of government alone but within the corridors of businesses across the country.

It is time for a strategic re-think of how we work and grow.

#productivity #efficiency #supplychainmanagement